ARTICLE DATE: 1994

It was one of those days that drives an editor crazy. Nothing worked, nothing fit, and one of the production workers switched “Beaver” for “Bearcat” with almost disastrous results. I was ready for the long ride back home in my son’s Honda Civic hatchback with a twelve-valve engine in it. He loves the car and the engine has been nothing but dependable.

The ride from Canoga Park to Apple Valley takes about two hours, and travels through some very pretty, though hostile, country on six-lane speedways that local TV newsmen call the “Autobahn Free way” rather than the correct “Antelope Valley Freeway,” because it is well-known for the high speeds the cars travel at. Seventy will get you run over. A nice comfortable 80 to 85 will keep you out of trouble.

This, almost-new highway turns into a two-lane desert road for the last 50 miles with nothing to amuse you but an occasional coyote or jackrabbit scampering by. When it gets dark, it becomes necessary to slow the speed down to 70-75 mph in order not to overrun your lights. Whatever happened to the 55 mph limit? Beats me, but it is suicide to attempt to be legal on these roads. The Honda engine loves it, though, always urging you to go faster.

As I was climbing the last hill on the freeway before Canyon Country, I saw it coming up in the distance, traffic slow down, then, a little further ahead, traffic stoppage. That was when the urge consumed me to pull back on the wheel and take to the skies and fly over the heads of the thousands of commuters heading home.

I looked at the speed indicator and, since I was still traveling 45 to 50 mph indicated, I just pulled back on the column stick and the Honda broke ground. It started climbing at about 1000 feet per minute and soon I was high above the local roads, stop lights, and Highway Patrol Officers. What a way to travel!

The little Honda engine was cranking around 5800 rpm, so I reduced the throttle to about 5000. The twelve-valve, four-stroke never sounded better. No, this is not a dream; I’m simply putting two events together in my mind.

The owner of Canadian Airmotive in Delta, British Columbia, Canada, had called a few weeks earlier and wanted to know if I would be interested in attending a press conference about their new product that they appear to be very proud of, and rightfully so. It’s a 100 hp four-stroke engine for under $6000 (1994) delivered into the USA.

Yes, it has a prop drive and every thing else necessary to bolt it to your fire wall and fire it up. When the company called, I wanted to make sure that they knew my position on engines that had belt-driven cam shafts. Unfortunately, almost all small overhead cam engines have them now, so there isn’t much anyone can do about it.

I was informed that they were about to change my mind. Okay by me, if it is one thing that I am noted for, it is the flexibility of my permanent positions. Every time I fly from Southern California to the Great Northwest, I sit with my eyes glued to the passing scenery below.

This has to be one of the most scenic flights in the world. Mother Nature cooperated this time with Chamber of Commerce weather all of the way. I had to change planes in San Jose, which meant we took off directly over San Francisco, the Golden Gate Bridge, Alcatraz, and the Delta. What a sight!

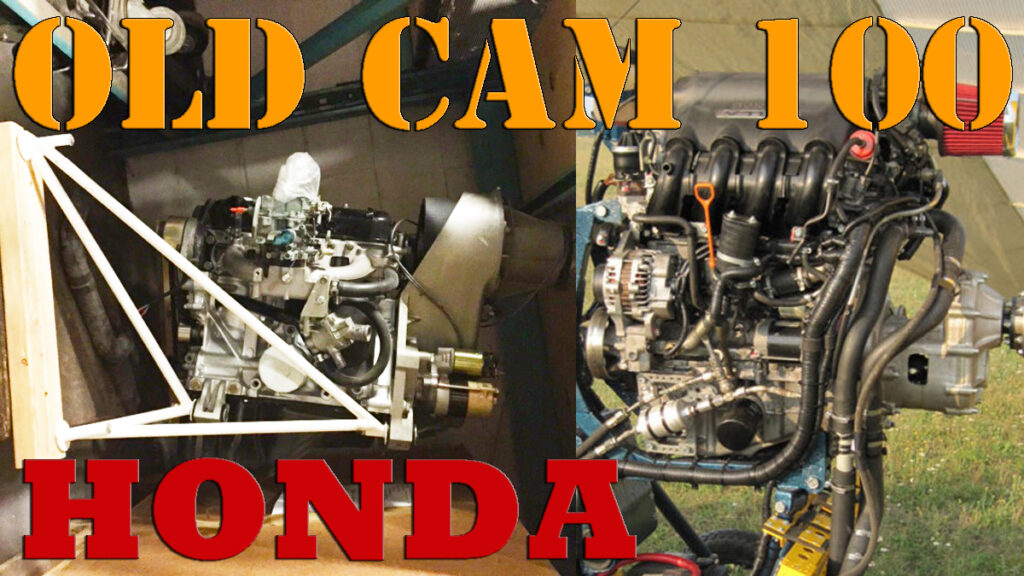

The Cam 100 is derived from a twelve-valve Honda Civic engine. The engine fit very nicely into a Malcolm Merlin. Only the cowling had to be changed.

As we progressed northward, our route took us over Crater Lake, which was ringed with a fresh snowfall. We then passed Mount Shasta, and, a short while later, the Three Sisters, Mt. Saint Helens, just north of Portland, Oregon, Mount Hood, Mount Rainier, and Mount Baker, the closest member of the chain to the Canadian border.

The MD-80 began its let down over Seattle and I looked down as we passed over Boeing Field, then Arlington, where the EAA Fly-In is held each year. When Mount Baker appeared off the left wing, I knew we were close. I love flying over seaports such as Seattle, Tacoma, Bremerton, Everett, and Vancouver. My flight was picture perfect.

After a short drive from the airport in my rental car, I arrived at the plant, located just south of the International Airport. It was then that I realized that this company must be run by some pretty successful folks. This was definitely a class act.

The man behind the company and the engine is Don Arney, who is dedicated to providing the best engine possible for the price. When you walk into the building, the first thing you see in the reception room is their pride and joy, a fully assembled Honda engine all chromed up and looking potent and pretty.

A couple of the company’s engineers stopped me and we spent the next few minutes talking with them about their engine. In the rental car, however, I had heard a weather report and it predicted heavy rain the next couple of days. I finally broke into the conversation and said, “Hey, if you guys want some color photos of your engine and your plane we had better go flying like now.”

So within a couple of minutes, we had all piled into a new Ford Explorer, with the works, and were headed for a little grass strip in Delta, B.C., alongside the bay. There were about 30 real interesting planes parked in hangars and tied down. There were Beavers, Trojans, Harvards, and a whole slew of homebuilts, some I recognized and others I didn’t.

The local flying club even had a Piper J-5 Cruiser for rent. Not bad. As I was admiring the old three-holer I heard an interesting sound that I had not heard before. I looked around the hangar and there it came, an old friend of mine, a Malcolm Merlin with a Canadian Air Engine installed. This was the very aircraft that I had flown earlier in the year with a Rotax 65 hp two-stroker for power, so I figured to get a good basis for comparison.

I spent the next half hour checking the nuts and bolts to make sure that everything was bolted or welded together securely. It was. I climbed aboard this Canadian-designed, side-by-side trainer and taxied to the departure end of the finely mowed grass runway.

Other pilots had also heard the weather forecast and the pattern was busy. Pattern? What pattern? There were planes all over the sky, they all appeared to know what they were doing, and I didn’t see many bent airplane parts scattered around the area, so I figured that was how they flew up here. They looked like my kind of pilots. Do your own thing! (safely)

The sun was darting in and out of the gathering clouds, and when I finally saw an opening, I shoved the throttle forward. Whoa Nellie, away we went! That little engine really moved that big Merlin on the soft, wet grass.

I popped up the tail, applied a little back pressure on the unique forked yoke, and immediately the Merlin broke ground. When I had reached a thou sand feet I throttled back to 5000 rpm and headed for a clear hunk of sky with very little air activity.

There were airports all over the place, including Vancouver Inter national, and I sure didn’t want to tangle with the Canadian version of the Feds. I had already test-flown this aircraft several hours before, and it has become one of my favorite aircraft.

It is an absolute natural for the new Primary Aircraft Category the FAA is plodding toward. When they removed the Rotax and installed the Air motive 100, the extra power added a little left turn to the aircraft. Other than that, the Honda flew that big airplane very well.

I particularly liked the lack of two-stroke vibration, the high-pitched scream, and the smoothness of sound. I flew the aircraft at a variety of power settings, from full throttle to medium-low idle, and the smoothness was there at every setting I tried.

By this time, the air craft and engine will have had almost 150 hours in its initial testing procedures. Two full-time pilots keep the bird in the air every nice day, flying around for hours at a time, checking the engine at all power settings.

Another test engine was torn down at 100 hours and there was no discernible wear. Everything was still within the same tolerances as when it was built. A third test engine is mounted on a test stand that can be wheeled outdoors into a test shed and run at full power. This engine has way over 100 hours on it, and it shows no sign of wear either.

TECHNICAL SPECIFICATIONS

-

Type: four-cylinder, four-stroke, in-line, liquid-cooled, overhead camshaft, normally aspirated.

-

Displacement: 1488 cc (90.7 inch 3)

-

Power Output: 100 hp (75 kw) at propeller flange

-

Reduction Ratio: 2.4:1 (6000 rpm engine/2500 rpm prop)

-

Bore: 74mm (3.07 in)

-

Stroke: 86.5mm (3.41 in)

-

Max full power run time: five minutes

-

Weight: 224.3 lbs (101.9 kg) (See weight specification sheet)

-

Direction of rotation: Clockwise (looking at face of prop flange)

-

Fuel Required: 90 octane unleaded minimum (R + M)/2. Can also use 100LL aviation gasoline

-

Cooling: Water-glycol mixture. (Water pump driven by camshaft belt.)

-

Cylinder Head: One-piece, aluminum, cross-flow design

-

Block: One-piece aluminum with reborable cast-iron liners

-

Compression Ratio: 9.2:1

-

Crankshaft: Fully girded, hardened, five main bearings of precision insert type

-

Camshaft: Cast alloy, head treated, parkerized

-

Lubrication: Full pressure, internal gear-type pump wet sump

-

Oil Quantity: 3.5 liters (3.7 US quarts)

-

Ignition: Dual digital electronic ignition with programmed automatic advance feeding single plug/coil units

-

Alternator: 15 Amp direct drive

-

Carburetion: Two-barrel progressive opening downdraft

-

Mixture Control: Back suction type controlled from instrument panel

-

Reduction System: 100mm (3.93 in) HTD cog belt

-

Fuel Consumption: specific 0.41 Ib/bhp/hr @ 80 per cent power

-

Oil Type: 5W30 synthetic

-

Starting System: Electric gear reduction starter

Officials of the company did their homework on this engine conversion. Computer read-outs of all cars ever brought into the country were examined, as well as repair records of their power-plants.

Initial costs and costs of parts were also worked into the formula, and the Honda Civic engine with the twelve valves came out the winner. They are easy to get, they have an excellent repair record, and they are readily accepted as a fine engine by thousands of satisfied motorists.

Used engines are purchased from various vendors and torn down completely. The parts are scanned for minor cracks and each part is miked for tolerances. Each part is then evaluated, after which, it is either discarded or accepted. Pistons, rings, bearings, valves, and other critical parts are replaced with new ones.

A specially designed propeller reducer drive is then attached to the front of the engine. A stock Honda Civic carburetor is then modified, taking off the smog parts not required for aircraft use, and reinstalled. Special liquid-cooling ports are installed so that coolant can be routed to the radiator, and then bolted to the engine.

All “AN” hardware is used, as is aircraft quality aluminum when special parts are required. A very large drive belt, from Italy, is then matched to the three-bearing drive shaft, which has been mounted in the specially designed prop drive housing.

Canadian Air Motive has a testing booth be hind their new plant where hundreds of hours at all rpm are being run off on the engine.

Currently, the ignition is on the rear of the engine, driven from the rear accessory case, as is the camshaft belt. Production models will have Hall Effect pickups on the front of the engine. As Sport Pilot Hot Kits & Homebuilts readers know, I’m not a proponent of auto engine conversions.

In this case, however, I was impressed. The Honda twelve-valve engine seems a natural conversion project, and the Airmotive 100 seems an excellent conversion, well-designed and quite strong.

Canadian Airmotive has designed this engine to be reliable and very affordable. In the USA, the price should be under $6000. Not bad for a 100 hp, four-stroke engine capable of almost unlimited running for many years. The engine weighs about 120 pounds more than a Rotax 582.

The Honda engine is all aluminum, which was another reason that Canadian Airmotive chose it for their product. As lovers of Japanese cars know, there are some great engines out there that have proven themselves over millions of trouble-free miles, but the Honda Civic engine is aluminum, which makes it even better for lightweight homebuilts.

There is no perfect product and this Honda has it faults. I am still not a big fan, to put it mildly, of plastic drive belts turning something as critical to flight safety as the camshaft. Yes, I am fully aware of how strong they are, and that in an automobile they last from 60,000 to 90,000 miles, which relates to a whole bunch of hours in an airplane.

What worries me is not the drive belts, but the owners of the airplanes. I can see one of these neat little engines parked in Arizona, tied down in the hot sun with the 150-plus temperatures in the cowling slowly cooking that nice strong belt, as well as the drive belt.

ENGINE AND ACCESSORIES — WEIGHTS

-

Base Engine Weight: 224.3 lbs (101.9 kg) on Certified Scale

-

Engine includes: Propeller speed reduction unit, alternator (15 Amp), Carb heat box, c/w filter, exhaust shroud, ducting and control cable, oil pump, oil filter, water pump,

thermostat c/w bracket, coolant fitting c/w brass fitting, filler neck Radiator cap, 1-1/4-inch hose from the thermostat to pump 1-5/8-inch hose from manifold to thermostat 1-5/8-inch hose from head to manifold, 1-5/8-inch hose from new fitting to thermostat Spark plugs, Carburetor Inlet manifold, Exhaust header with carb heat shroud, Starter, All bolts and clamps to hold above in place

You see, I have been around pilots for many years and I know for a fact that many of them have a lot to learn about proper aircraft maintenance. I just returned from the I AC Convention in Las Vegas, and was appalled at the large number of aerobatic pilots puffing away on cigarettes.

I hope they take better care of their airplanes than do of their bodies. That is my problem. I don’t believe that all pilots will inspect their drive and cam belts during the pre-flight inspection.

I have seen too many pilots jump in and go, without even a simple walk-around. How many times in the past year was someone killed because they failed to remove gust locks from the control surfaces? One is too many.

Even the pilots who do check the belts during their preflight might not bother to have it changed, or change it themselves. Many will be tempted to get “one more flight out of it” before replacing it.

The cam belt on the rear of this engine is easy to inspect. It is out in the open and can be carefully inspected for any wear. Changing it is another story. About six bolts must be removed, and then the cam gear and the crankshaft must be keyed so that the belt can be replaced in the same location.

You can’t believe the destruction that can result from a cam drive which is improperly timed. I also know that in order to supply good, inexpensive engines to the many homebuilders who want four-strokers, some compromises must be accepted.

As long as the installation would allow me to carefully inspect the belt before each flight, I wouldn’t be concerned flying behind one with my family, because I thoroughly preflight any aircraft I fly and if I find something I don’t like, I don’t fly until it has been fixed.

The engine that I flew in Canada had a specially built muffler on it that kept the engine noise very low. The radiator installed kept the temperatures in the correct range. It is my impression that this company is dedicated to supplying the homebuilt industry with quality engines that have been damn-fool-proofed, to the best of their ability.

Why don’t they make new Honda engines available? Two reasons…

1. They would be too expensive and Honda won’t sell them any because the giant auto company doesn’t want the liability risk of selling any of their engines to anyone who is going to install it in an aircraft. This is not unique to Honda; I know of no engine company other than Lycoming, Continental, and Rotax that will sell anyone an engine who is going to put it in an airplane.

2. Canadian liability laws are not as lenient as they are in the States, but the engine manufacturers are still very leery of the hordes of lawyers who scan the papers every hour looking for someone that is in a position to sue someone for product liability. And . . . you must admit that car engine manufacturers have some very deep pockets, indeed.

For more information on this great 100 hp, four-stroke engine, search Google “Canadian Airmotive” for further information.

WAY BACK THEN…

Powering our way into the future

“Engine technology perhaps more than any other aspect of our sport, has grown by leaps and bounds in the past ten years”

Produced by Canadian Airmotive, the CAM 100 is a 100 hp aviation engine derived from the Honda Civic auto engine.

When Sport Pilot first hit the stands ten years ago, it was a different kind of sport aviation atmosphere. For one thing, the engine options for those on the low-end of the power spectrum were great, while those on the high power end of it, the outlook was dim. How times change!

These days ultralighters have fewer options (though the choices are probably of higher quality), and those in search of high-end muscle have more avenues than ever before. The reason for the change is twofold.

On the low-hp side of the coin, the overwhelming success of Rotax has driven most of their competitors out of the business. Neither Cuyuna, Kawasaki, nor Konig are in the ultralight power business any more.

These days when you go looking for an ultralight engine, the question is, what kind of Rotax do you want? One of the most popular two-stroke aircraft engines of all time is the Rotax 582, mounted here on the frame of a Kitfox.

In fact, most of the really significant advances in light aircraft engines have come courtesy of Rotax. The introduction of the 65-hp two-stroke 582 gave the company an engine which could power the slightly heavier Experimentals finding favor with many homebuilders.

It also proved an excellent choice for builders who wanted better performance from their two-passenger ultralight-type Experimentals. One such ultralight, the Quicksilver GT-500, recently earned FAA certification with a 582 installed. Which makes the 582 an FAA-certified engine (in the GT-500 anyway).

In 1991 Rotax did themselves one better by introduced the new opposed four-cylinder, four-stoke 912. Producing better than 80 horsepower (and that’s no hype), the 912 has become the engine of choice for advanced lightweight air craft. Look for the 912 to get its FAA walking papers within the foreseeable future, as well.

At last check, the most popular light power solution of the 1960s and 1970s, namely the VW conversion, was fading fast in the early 1990s. Sold by a variety of firms, these engines once commanded a significant portion of the home built engine market.

The newest conversions to come down the pike are of engines produced in the Far East. The CAM 100, manufactured by Canadian Airmotive of British Columbia, is based on the Honda Civic engine. Given a re-profiled cam and beefier crank, the CAM 100 has been getting rave reviews from builders who installed the engine in their homebuilts.

Another conversion, the Subaru E-81, is also taking up where the VW left off. After appropriate modifications are per formed, the E-81 seems to make a first-rate aircraft engine.

On the other side of the carb, those pilots looking for high power solutions are busy sorting out their options.

When in years past the name of the game was either Continental or Lycoming (with a few Franklins and Jacobs thrown in for good measure) today’s pilots might just as well say Buick or Ford instead.

The big reason for turning to the auto conversion is money. Because of the astronomically high prices of high-powered certified aircraft engines, highly reworked big-block auto engines suddenly make lots of sense. One BD-4 project says it all.

Houston native Ray Ward was looking to get max power into his homebuilt, which he calls a BD-4 Super Sport. But to get a Lycoming or Continental engine of 400 or more horses, he would have had to shell out more than $50,000. Then you’re talking more big bucks down the road when it’s time for rebuilding the thing.

Ward’s solution was to use an auto engine, a highly modified big block Chevy which puts out better than 400 hp for pennies on the dollar and which can be rebuilt for a small fraction of the cost of overhauling a comparable certified engine.

So lots of auto engines are going into homebuilts these days. George Morse, for one, continues to do nice things with Olds engines. His Prowler kitplane, for instance, can get better than 200 mph from an highly modified Olds 215. Flight Escort Wings all-composite scale P-51 look-alike also makes use of a Oldsmobile V-8 for power.

In recent years we’ve also reported on experiments with other kinds of power, including turbines and ducted fans. We’ve even heard rumor of a steam-powered homebuilt in the works. While we have yet to see our first turbine-powered Kitfox, we wouldn’t be surprised to see one in the near future.

After all, there’s already a turbine-powered home built helicopter, the Cobra Mustang Predator, flying. So why ask why!

Be the first to comment on "History Of The Honda CAM 100 Engine"